GreenStar Insulation

781-810-4858

781-810-4858

Greenstar Insulation: Advanced Thermal barrier Insulation application

performed at a competitive price By

highly skilled, competant, honest workers

Honesty, Integrity, and Quality Workmanship

Green Star is a unique insulation firm which combines advance thermal barrier insulation with highly skilled mold experts and anti-mold techniques to solve all your thermal issues and prevent mold from occuring or re-occuring.

Greenstar employs innovative methods to prevent condensation and heat/cold loss by utilizing spray foam insulation in conjunction with mold removal methods. Greenstar personnel are the best spray foam insulators with the most experience in the business.

We kill the mold and then coat the problematic areas and building materials with spray foam insulation or another insulation that will solve your buildings needs.

Greenstar is located in Dedham, Massachusetts and our service region extends throughout New England. Greenstar is the cutting edge of construction materials. Our rigs come to your building site and manufacture custom building materials for insulation, roofing, siding and use innovative methods for mold removal, prevention, eradication.

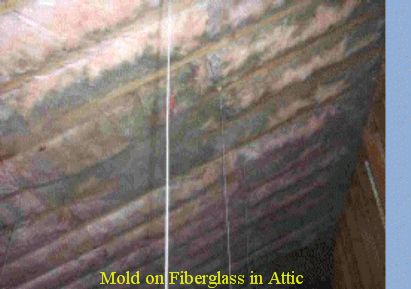

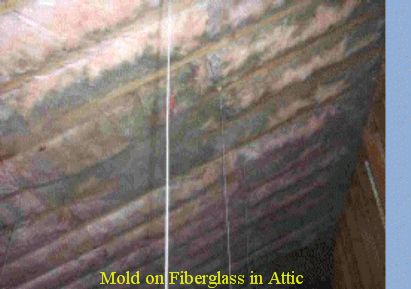

Mold removal in an attic/crawlspace by traditional methods is a costly, time consuming and hazardous endeavor. However, with Greenstar Foam, it's quick, easy, non-toxic, less expensive, permanent and cost effective. Get more information and learn about attics and crawlspaces in the mold in attic/crawlspace section of our website.

We hope you will find this website helpful in making the right decision about your home's insulation. Please visit our Resources section for further information and to view a wonderful video concerning foam insulation.

Lastly, if you insulate with Greenstar Spray Foam you can qualify for great rebates from your local energy company as well as your state and the federal government. Spray foam insulation is the right choice when dealing with mold-in-attic, wall and crawlspace problems: call us now: 781-810-4858 or fill out the form below and we'll get back to immediately.

Important information prior to deciding on any insulation for your home:

1. Foam Insulation Compared to Cellulose and Fiberglass Insulation.

2. Why Is The R-Value Myth Perpetuated?

3. Vapor Barriers And Why I Should Be Concerned With Fiberglass and Crawlspace Insulation.

4. Air Currents Within Fiberglass and Cellulose Insulations.

5. Air Penetration Within Fiberglass and Cellulose Insulations.

Foam Insulation Compared to Cellulose and Fiberglass Insulation and the R-Value Myth

The Great Myth of Modern Home Construction is the 'R-value' measurement. R-values have been peddled to us for so long that they have taken on a 'Chiseled-In-Stone' status, even with some otherwise knowledgeable contractors and architects. The saddest part of this is that the R-value by itself is almost a worthless number, as it is impossible to define insulation effectiveness by this number alone

WHY IS THE MYTH PERPETUATED?

It definitely favors 'traditionally used' fiber insulations made by large International Corporations, who regularly lobby & contribute to keep it in place, despite peer reviewed science that shows its limitations.

What would the R-value of insulation be after it has been submersed in water or had a 20 mile per hour wind blowing through it? Obviously the 'Effective' R-value of fiberglass, cellulose, wool and/or cotton insulation would go to zero, but Spray Foam Insulation would be largely unaffected. Again, R-values are 'funny' numbers; they are meaningless unless we know all the relevant factors.

The use of R-values as the only criteria for insulation is absolutely ridiculous, yet we have Government Agencies mandating R-values of 30 to 50 today, despite any actual science to support these levels. Traditional insulation having an R-25-value installed in a wall/floor/ceiling, but not properly sealed will allow air to travel through it and/or moisture to saturate it - providing no real R-value at all.

R-values are a result standardized testing of heat flow through insulation in a sealed test fixture under controlled laboratory conditions, but these tests are not even remotely associated with the real world environment where insulation is commonly installed.

To calculate the actual installed performance of insulation, we also need to know its resistance to air penetration, to internal air currents, to liquid water, and to water vapor drive. What really matters is the 'effective' R-value when insulation is subjected to these real world conditions.

Fiber insulation is generally assigned an R-value of approximately 3.5 per inch, yet it can only achieve this value when tested in an absolute zero air-movement and zero moisture environment. Zero wind and zero moisture are not real-world conditions, as all homes leak air and water vapor from the outside air, showers, cooking, breathing, etc., constantly moving through our homes.

If the attic is not properly ventilated on a fiber insulated home, the water vapor generated inside a house will very quickly semi-saturate the insulation above the ceiling and in the walls. Even small amounts of moisture will cause a dramatic drop, as much as 50 percent or more, in fiber insulation's performance

Vapor Barriers and why I should be concerned with Fiberglass and Cellulose Insulation.

Because such small amounts of moisture have devastating effects on fiber insulations performance, it is recommended that fiber insulation have a vapor barrier installed on the warm side of the insulation. This recommendation poses a completely new problem, which is the warm side of the wall?

Obviously, the warm side changes from summer to winter, even from day to night. If it is 30 degrees outside, the inside of an occupied house is certainly the warm side, conversely, during the summer months, when the sun is shining; the warm side is the outside of the wall.

Occasionally, a novice will try to put vapor barriers on both sides of the insulation, but this proves to be disastrous because the vapor barriers will stop most of the moisture but not all. Small amounts of moisture will still move into the fiber insulation between the two vapor barriers and become trapped. It will accumulate as the temperature swings back and forth altering the direction of vapor drive forces, leading to significant mold growth, health problems, building rot and increased energy costs.

Fiber insulation must be ventilated on one side or you can end up with serious mold growth problems, as illustrated in the image below. This required ventilation also allows air movement within the fiber insulation, significantly reducing its effectiveness AND R-Value.

Spray Foam Insulation does not have these limitations. It creates its own air-tight seal, while still allowing water vapor to pass through without accumulating or affecting its performance. This complete insulation, air barrier and moisture management solution is what makes Greenstar Spray Foam Insulation the intelligent choice for your home.

Air Currents Within Fiberglass and Cellulose Insulations.

We all understand air penetration through the walls of our homes; we can even feel it in some homes when the wind blows. But what most people, including many engineers, do not realize is that there are very significant convection currents occurring within the traditional insulations. These convection currents rotate vast amounts of air, leading to significant energy losses.

These convective air currents are not fast enough to feel and are difficult to measure without sensitive instruments. Nevertheless, these air current are constantly carrying heat from the bottom of the fiber insulation to the top side, letting it escape.

If we seal off this air movement with traditional insulation, we seal in the water vapor where it will condense into a liquid becoming a source of moisture for mold growth and rotting of your home. This water vapor and resulting condensation will also seriously decrease the fiber insulation's R-value and increase your energy costs. The only way to deal with fiber insulation is to ventilate, but to ventilate means allowing air movement, which decreases the R-value and increases your energy costs.

Once again, Spray Foam Insulation does not have these limitations, because it creates its own air-tight seal, while still allowing water vapor to pass through without accumulating or affecting its performance.

Air Penetration Within Fiberglass and Cellulose Insulations.

The filter for most furnace filters is made from fiberglass, the same spun fiberglass used as insulation. Fiberglass is used for an air filter because it has low resistance to the air flow, and it is cheap. In other words, the air flows through it very readily.

There are tremendous air currents that blow through the walls of a typical home. To test this one can hold a lit candle near an electrical outlet on an outside wall when the wind is blowing. The average home with all its doors and windows closed has a combination of air leaks equal to the size of an open door.

Even if a perfect job of installing the fiber insulation is performed in a home and air infiltration is brought close to zero from one side of the wall to the other, we still do not stop the conductive air currents from moving through the insulation itself vertically both in the ceiling and the walls.

Spray Foam Insulation absolutely protects itself from air infiltration and cannot support internal air currents, as the bonding of the spray liquid plus the expansion of the foam (as it cures) creates a total seal. The value of this total seal is almost impossible to overestimate, because most of the heat losses in the walls and ceilings of homes have to do with the air-seal rather than the insulation’s R-Value.

Air infiltration can most effectively be stopped with Spray-In-Place Foam Insulation. It is the only material that when applied will expand to fill all the corners, the cripples, the double studs, bottom plates, top plates, etc. The R-value of a material is of no interest or consequence if air can get past it!

R-value tables are part of the Myth; they show Spray Foam and the fiber insulations side by side, implying they can be compared. The fact is, without taking installation conditions and air movement into account, these comparisons are meaningless. Spray Foam provides its own vapor barrier, water barrier, and wind barrier.

No other insulation material can even come close to Greenstar Foam Insulation’s installed effectiveness. Using spray foam insulation is guaranteed to save you energy and provide a healthier, more comfortable home for you and your family.

You only insulate once, but you're going to pay for your Heating and Cooling energy costs for a long time. Choose Greenstar Foam Insulation, it's the intelligent choice.

Air Currents Within Fiberglass and Cellulose Insulations.

We all understand air penetration through the walls of our homes; we can even feel it in some homes when the wind blows. But what most people, including many engineers, do not realize is that there are very significant convection currents occurring within the traditional insulations. These convection currents rotate vast amounts of air, leading to significant energy losses.

These convective air currents are not fast enough to feel and are difficult to measure without sensitive instruments. Nevertheless, these air current are constantly carrying heat from the bottom of the fiber insulation to the top side, letting it escape.

If we seal off this air movement with traditional insulation, we seal in the water vapor where it will condense into a liquid becoming a source of moisture for mold growth and rotting of your home. This water vapor and resulting condensation will also seriously decrease the fiber insulation's R-value and increase your energy costs. The only way to deal with fiber insulation is to ventilate, but to ventilate means allowing air movement, which decreases the R-value and increases your energy costs.

Once again, Spray Foam Insulation does not have these limitations, because it creates its own air-tight seal, while still allowing water vapor to pass through without accumulating or affecting its performance.

Air Penetration Within Fiberglass and Cellulose Insulations.

The filter for most furnace filters is made from fiberglass, the same spun fiberglass used as insulation. Fiberglass is used for an air filter because it has low resistance to the air flow, and it is cheap. In other words, the air flows through it very readily.

There are tremendous air currents that blow through the walls of a typical home. To test this one can hold a lit candle near an electrical outlet on an outside wall when the wind is blowing. The average home with all its doors and windows closed has a combination of air leaks equal to the size of an open door.

Even if a perfect job of installing the fiber insulation is performed in a home and air infiltration is brought close to zero from one side of the wall to the other, we still do not stop the conductive air currents from moving through the insulation itself vertically both in the ceiling and the walls.

Spray Foam Insulation absolutely protects itself from air infiltration and cannot support internal air currents, as the bonding of the spray liquid plus the expansion of the foam (as it cures) creates a total seal. The value of this total seal is almost impossible to overestimate, because most of the heat losses in the walls and ceilings of homes have to do with the air-seal rather than the insulation’s R-Value.

Air infiltration can most effectively be stopped with Spray-In-Place Foam Insulation. It is the only material that when applied will expand to fill all the corners, the cripples, the double studs, bottom plates, top plates, etc. The R-value of a material is of no interest or consequence if air can get past it!

R-value tables are part of the Myth; they show Spray Foam and the fiber insulations side by side, implying they can be compared. The fact is, without taking installation conditions and air movement into account, these comparisons are meaningless. Spray Foam provides its own vapor barrier, water barrier, and wind barrier.

No other insulation material can even come close to Greenstar Foam Insulation’s installed effectiveness. Using spray foam insulation is guaranteed to save you energy and provide a healthier, more comfortable home for you and your family.

You only insulate once, but you're going to pay for your Heating and Cooling energy costs for a long time. Choose Greenstar Foam Insulation, it's the intelligent choice.

Call us now at 781-810-4858 and start saving money or just fill out the form below and we'll get back to you as soon as possible

Serving the communities of

Massachusetts, Rhode Island and New Hampshire

Our spray foams are similar, have better insulation properties and are cheaper than Icynene, Demilec and other brand name products.

Hits received by this website

Home Page About Us Projects Testimonials

Contact Us Rebates/Coupons Resources Prior to our Arrival